Heavy solid paraffin is one of the important petroleum derivatives produced in the refining industry, primarily consisting of long hydrocarbon chains and having a higher melting point compared to light paraffins.

In fact, during the production of paraffin from crude oil, the portion of the product that includes wax with a relatively higher oil content falls into the “heavy” grade category. Due to its greater hardness, higher durability, and higher melting point, it is used in heavier industries.

Our company, Palayesh Gostar Tivan, as a producer and supplier of this product, is ready to supply the export-grade “Heavy Solid Paraffin” to various industries with high quality, bulk supply, and competitive pricing.

Why Choose “Heavy Solid Paraffin” from Palayesh Gostar Tivan?

* Direct production without intermediaries: Palayesh Gostar Tivan Company, as the manufacturer, manages the complete production process from petroleum feedstock to supply; therefore, it is possible to offer “bulk heavy solid paraffin” at a suitable price.

* Export Quality: The product is produced in accordance with international standards; technical analysis is provided for each shipment, and you as the buyer can order with confidence.

* Wide Range of Applications: “Heavy Solid Paraffin” is one of our key products with diverse industrial applications; this means you receive a cost-effective and multi-purpose raw material by purchasing from us.

* Support Services: Our sales and technical units are ready to advise on the appropriate grade, volume, packaging conditions, and delivery method. You can proceed to “buy heavy solid paraffin” starting today.

* Fast Delivery and Volume Flexibility: Whether you intend to “sell heavy solid paraffin” or be a consumer, we have the capacity to supply bulk orders.

**Extensive Applications of “Heavy Solid Paraffin”**

*In the Candle Making Industry, High Regulations and Precise Shapes*

One of the important applications of “Heavy Solid Paraffin” is the production of molded candles. The higher melting point and harder structure of this product result in a more stable produced candle, with uniform burning and without producing excessive smoke. Lumo Oil+1

*Electrical Insulation and Fiber Copy Industries*

Due to its crystalline structure and high stability, heavy solid paraffin can be used in the insulation of wires and cables, or coating components that require resistance to electrical current. Wikipedia+1

*Plastic, Rubber, and Polymer Compounds*

In the production of rubber or plastic products, adding “Heavy Solid Paraffin” to the formulation can serve as a lubricant, improve the molding process, increase flexibility, and reduce cracking.

*Production of Wax, Polish, Waterproof Coatings*

This product is also used in the production of industrial waxes, wood and metal polishes, waterproof coatings for cardboard or wood—especially when greater hardness, durability, and a higher melting point are required.

*Tanning, Woodworking, and Packaging Industries*

For impregnating leather or cardboard against moisture, or use in wood coating processes, “Heavy Solid Paraffin” is a desirable choice; because it is harder and creates a more stable protective layer.

**Physical and Chemical Characteristics of “Heavy Solid Paraffin”**

* Crystalline structure of long hydrocarbon chains (typically C20-C40); alphawax.com+1

* Relatively high melting point (e.g., in the range of approximately 58 to 65 degrees Celsius or higher depending on the grade);

* High density (e.g., greater than ~0.9 g/cm³) in the heavy grade;

* Resistant to oxidation, colorless or nearly white, odorless or with a very slight odor;

* Insoluble in water but soluble in organic solvents;

* Variable oil content within the wax; the heavy grade may have more oil, which increases flexibility or lubricity; infinitygalaxy.org+1

**Review of Advantages and Disadvantages of “Heavy Solid Paraffin”**

*Advantages*

* Adaptability in heavy industries: It is a very suitable option for applications requiring hardness, high melting point, and durability.

* Economic efficiency for bulk orders: “Bulk heavy solid paraffin” can be procured at a suitable price.

* High physical stability: Due to its harder structure, it lasts longer under thermal and environmental conditions.

* Possibility to select a grade matching your specific industrial need (e.g., oil content, melting point, color) – this means you can choose the product precisely according to your process.

*Disadvantages*

* Higher production cost compared to lighter grades: More precise refining and supplementary processes may increase the cost.

* Less flexibility compared to lighter waxes: If your application requires a softer material or faster melting, it might not be the suitable option.

* Some very delicate applications (e.g., sensitive cosmetic products) might require a lighter grade, so it should be noted that “Heavy Solid Paraffin” is only suitable for specific conditions.

**Review of Product Strengths and Weaknesses**

*Strengths*

* Production according to international standards

* Variety of grades suitable for different industries

* Capability to supply bulk and export orders

* Consistent and controlled quality

*Weaknesses*

* Requires technical knowledge to select the appropriate grade (if chosen incorrectly, optimal performance may not be achieved)

* For very sensitive uses, further refining or supplementary processing might be required

**Tips for Optimal Use of “Heavy Solid Paraffin”**

1. Before purchase, match the technical specifications (melting point, oil content, color, crystalline structure) with your production or process needs.

2. When ordering “bulk heavy solid paraffin”, be sure to consider the packaging conditions, delivery time, and transport costs—proper storage conditions directly impact quality.

3. When using in molding or injection, ensure the wax melting point is appropriate for your mold temperature and process.

4. If you have a reaction in the formulation (e.g., with tanning compounds, plastics, or coatings), обязательно perform sampling and testing.

5. Store the product in a dry, cool place, away from direct sunlight, and in sealed containers to ensure optimal performance.

6. When combining with other additives (e.g., in producing adhesives, lubricants, or coatings), pay attention to the compatibility of the wax with other compounds.

**Supplementary Suggestions for Product Pairing**

For maximum utilization of “Heavy Solid Paraffin”, we suggest using your product alongside one of the following:

* Vaseline: In industries that require a softer base material in addition to solid wax, combination can be considered.

* Liquid Paraffin (White Oil): In processes that require a lubricant or carrier material alongside solid wax, using liquid paraffin or a suitable grade along with “Heavy Solid Paraffin” might be advantageous.

* Foots Oil: For heavy industrial applications such as rubber or tire manufacturing, “Heavy Solid Paraffin” is often chosen alongside Foots Oil to create an optimal lubricant/wax combination.

Using these complementary combinations can reduce raw material costs, improve the efficiency of the final product, and optimize your order.

**Heavy Solid Paraffin Price, Buying and Selling Heavy Solid Paraffin**

*Factors Affecting Heavy Solid Paraffin Price*

The price of heavy solid paraffin is influenced by several key factors:

* Grade and oil content of the wax (lower oil content and more refining lead to a higher price)

* Melting point, viscosity, and hardness of the wax; grades with higher melting points usually have different prices.

* Order volume and packaging conditions: Bulk orders (“bulk heavy solid paraffin”) typically have more suitable prices.

* Oil market conditions and production costs, solvents, and refining process.

**Guide for Buying and Selling “Heavy Solid Paraffin”**

* To “buy heavy solid paraffin”, it is recommended to contact the company’s sales unit, specify the grade, volume, packaging, and your intended use.

* Selling bulk heavy solid paraffin is very cost-effective for traders or large industrial consumers.

* When concluding a contract, consider the technical specifications, delivery time, potential price fluctuations, payment terms, and quality guarantee.

* Request a Certificate of Analysis (COA) and product sample from the seller to ensure the product matches your specifications.

* Palayesh Gostar Tivan Company is ready to provide consultation, proforma invoices, and samples for industrial customers.

**Summary**

Heavy Solid Paraffin is a critical and multi-purpose raw material for major industries; from candle making and insulation to plastics, rubber, leather, and coating. If you are looking for a reliable supplier that offers quality, price, and support together, Palayesh Gostar Tivan will be a smart choice. Contact us today to “buy heavy solid paraffin” and benefit from the special bulk order offer.

**User Reviews in Online Stores regarding Heavy Solid Paraffin**

* “We chose the heavy grade for our molded candle production line; it had much better quality than the previous wax and produced less soot.”

* “The price for the bulk heavy solid paraffin we got was suitable, packaging was excellent, and delivery was fast.”

* “In the rubber production process, when we added this wax, cracking decreased and product flexibility improved.”

* “When buying heavy solid paraffin, we took a sample, checked the analysis, it fully matched the specifications; I recommend it.”

* “During our sale of heavy solid paraffin for export, all analysis documents and certificates were prepared, and the export process became much easier.”

**Heavy Solid Paraffin Product Technical Specifications**

* Country of Origin: Iran

* Brand: Palayesh Gostar Tivan

* Product Name: Heavy Solid Paraffin

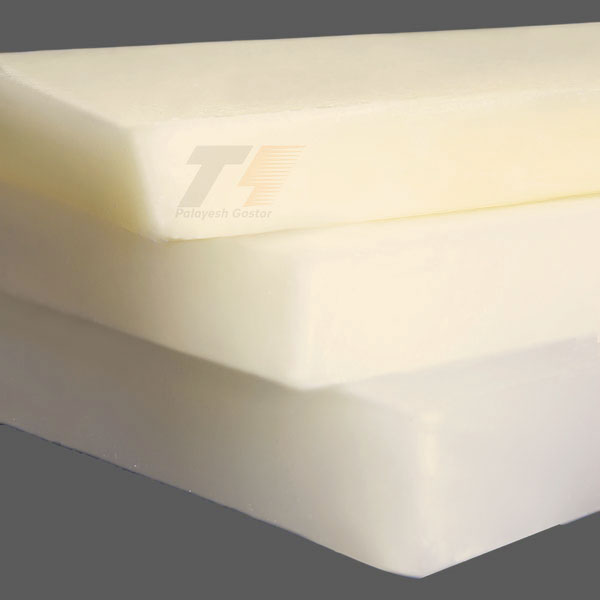

* Color: White or creamy white

* Odor: Odorless or minimal odor

* Physical State: Solid at room temperature

* Melting Point: Typically between ~58 to ~65 °C (depending on grade)

* Density: Approximately 0.9 g/cm³ or more (depending on grade)

* Oil Content: Variable, in heavy grade may be higher than light grades (example 5-7% or more)

* Packaging: Block or granules, 25 kg bags, cardboard boxes, jumbo bags, or tanker for bulk orders

* Package Weight: Varied; e.g., 25 kg bag, 800-1000 kg jumbo bag

* Package Dimensions: Varies depending on packaging type

* Standards: Produced in accordance with international standards such as ASTM, customizable for export

* Storage Conditions: In a dry, cool place, away from direct sunlight, in sealed and intact containers

* Applications: Candle making, insulation, rubber production, wood and metal coating, tanning, packaging, etc.

Reviews

There are no reviews yet.